Philtronics Digitalisation Project

The digital landscape looks very different to how it did 20 years ago when Philtronics was first established. Technology is constantly evolving, which means our everyday lives are changing too, especially within the workplace. As an electronic manufacturer, we know first-hand the importance of creating new technology. Equally, we know that utilising new technologies is essential for several reasons, such as security, data management, collaboration and much more. Within this case study, we will present the ways in which we have leveraged digital technologies to transform traditional processes, systems, and services into their digital counterparts.

Background

Our digitalisation project began following a comprehensive systems and process review, which was carried out in early 2023 by our Chief Technology Officer (CTO), Simon Street. Simon was able to identify areas within Philtronics’ systems and processes that could be improved and worked on with new technology and digital innovation. These digital technologies and tools were then incorporated into various functions to improve efficiency, productivity, and overall performance at Philtronics.

Digital Transformation

To ensure we got the most out of Simon’s research and findings, the project covered six different areas, with each area utilising unique technology and digital tools to achieve the best results.

These six areas included:

1. Integration of Digital Technologies

After Simon conducted his review, we knew integrating a variety of digital technologies would be a necessity for this project. This involved adopting and integrating various digital technologies such as cloud computing, data analytics, artificial intelligence, Internet of Things (IoT), and other digital tools into existing processes, as well as developing new digital solutions in some cases.

2. Data Management and Analytics

Data is vital in most industries, especially so in electronic manufacturing as data helps inform our planning and decision-making processes. Therefore, we ensured better management of our data by making use of analytics to derive insights and inform our decisions. This included collecting, processing, and analysing data to gain a better understanding of processes and trends.

3. Automation

The process of automation is a significant aspect of digitalisation as it involves the use of technology to better perform tasks or processes. We made sure to include this within the project as automations have many benefits, for example, increased efficiency, reduction in errors, and cost savings.

4. Improved Communication and Collaboration

We also focused on enhancing communication and collaboration within and outside the organisation. As part of our TRONICS values, teamwork is a crucial attribute for all team members to possess and utilise daily. So, it was important to optimise how everyone works together as a team, this included implementing collaboration tools, digital communication platforms, and project management systems.

5. Security and Compliance

As digital systems handle sensitive data, ensuring security and compliance with relevant policies and regulations was a vital aspect of the project. To ensure data security at all levels of the organisation, we applied secure digital measures to protect data and ensure privacy. As we work towards becoming a Cyber Essentials certified organisation, this aspect was particularly important to both the project and our certification.

6. Training and Change Management

Introducing new digital technologies requires employees to acquire new skills and adapt to changes in their work processes. Training and change management initiatives are vital to ensure a smooth transition and maximise the benefits of digitalisation. Philtronics will utilise the new Philtronics Academy to deliver training programmes to existing and new staff alongside the integrations and new technologies introduced.

While we continue to implement these areas of digital transformation, we began our journey with a simple yet impactful step; going paperless. For some businesses, going paperless is easily done, especially in our digital age, however, new digital technologies, processes, and training need to be put in place in order to make the transition as smooth as possible. Here are the changes we have made so far to make Philtronics paperless:

1. Our Purchase Orders and Supplier Order Acknowledgements are no longer printed and are stored electronically.

2. We no longer keep paper copies of our supplier delivery notes, they are simply scanned and saved electronically.

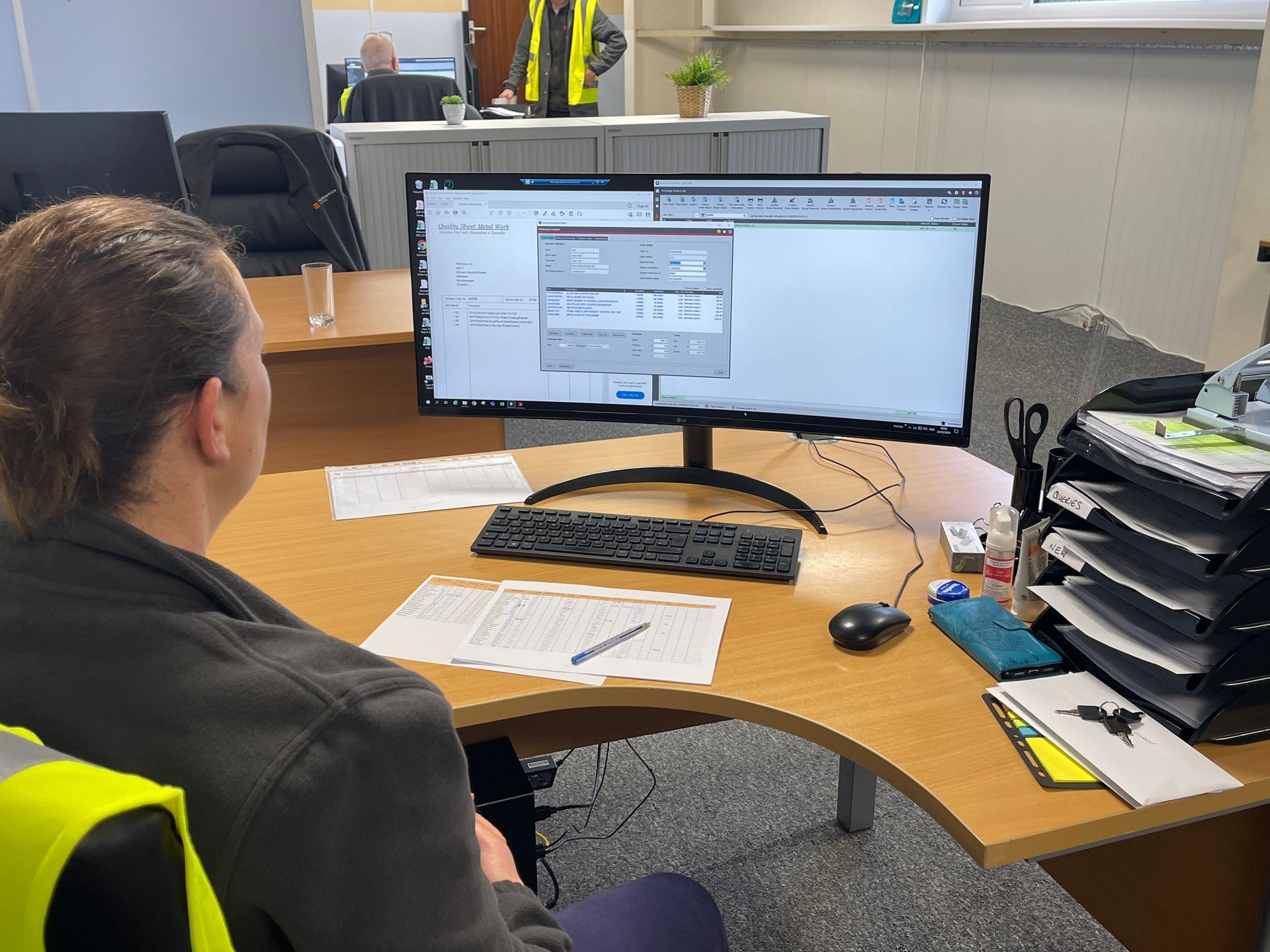

3. Following the purchase of wider screens, our Accounts Payable invoices and statements are handled digitally, and we no longer print them out.

4. We have stopped printing our Sales invoices, instead we hold electronic copies.

5. In Payroll and HR, our employees’ payslips were changed to an electronic version early last year. We also changed our absence management system, whereby employees now log their leave requests online, which streamlines the process and saves paper.

In the next phase of going paperless, we plan to issue our Production staff with tablets to better visualise and control our technical drawings.

The outcomes of this digitalisation project have been exceedingly positive; team collaboration and communication has improved, our data is more secure than ever, processes are faster and therefore more efficient, and team members feel confident using the new digital integrations thanks to relevant training.

LATEST NEWS